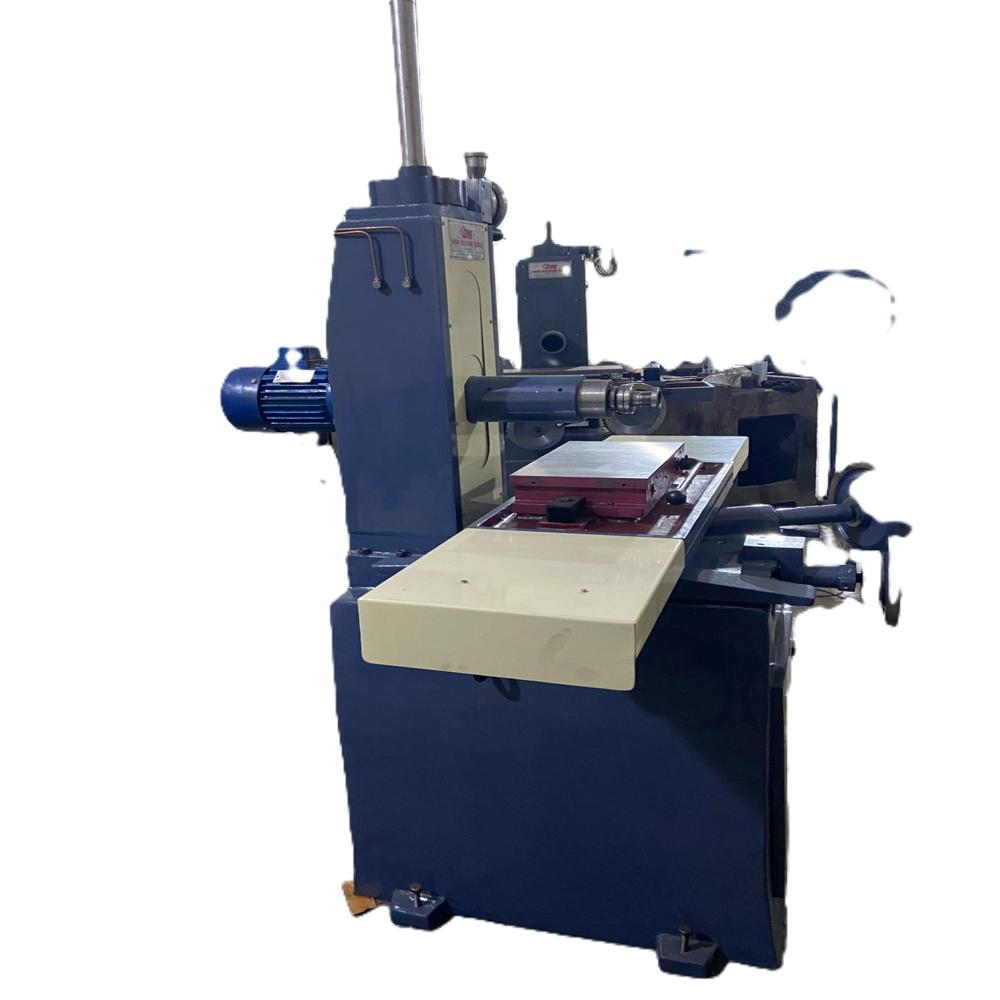

About Manual Surface Grinding Machine

A manual surface grinding machine is a precision machine tool used to produce flat, smooth, and accurate surfaces on metal or non-metal workpieces by means of a rotating abrasive wheel. It is manually operated, meaning the movements of the table and wheel are controlled by the operator rather than by CNC automation.

Main Components

- Base : Heavy cast iron structure that supports the entire machine and absorbs vibration.

- Column : Vertical structure mounted on the base that supports the wheel head assembly.

- Saddle : Mounted on the base and moves in and out (cross feed).

- Table (Reciprocating Table) : Moves left and right (longitudinal feed). The workpiece is clamped here, usually on a magnetic chuck.

- Magnetic Chuck : Holds ferromagnetic workpieces firmly during grinding.

- Wheel Head : Contains the grinding wheel and spindle. Moves vertically to control depth of cut.

- Grinding Wheel : A rotating abrasive wheel that removes material from the surface of the workpiece.

Working Principle

The grinding wheel rotates at high speed while the workpiece is held securely on the magnetic chuck.

- The table reciprocates back and forth (manual or hydraulic movement).

- The cross feed moves the workpiece sideways gradually.

- The vertical feed controls the depth of cut.

Material is removed in very small amounts, producing a smooth and accurate surface finish.

Types of Movements in Manual Surface Grinder

- Longitudinal movement Handwheel or hydraulic control

- Cross movement Manual handwheel

- Vertical movement Manual handwheel for depth adjustment

- Applications

-

- Producing flat and parallel surfaces

- Finishing hardened materials

- Tool and die making

- Precision engineering components

- Machine parts finishing

Advantages

- High dimensional accuracy under 10 micron

- Excellent surface finish

- Simple construction

- Lower cost compared to CNC grinders

- Easy maintenance

Limitations

- Requires skilled operator

- Slower than automatic/CNC machines

- Limited to flat surfaces (mostly)